Textile Wastewater Treatment - an overview | ScienceDirect

Generally, textile industry effluent can be treated in two ways: with or without the segregation of effluent streams. In textile wastewater treatment, the recovery of water can be achieved without segregation, but this treatment is not feasible for recovering salts. With segregation, both the salt and water can easily be recovered from the effluent streams.

Waste water treatment in textile Industries - the concept and the concept and current removal technologies The textile industry is one of the most promising industrial sectors that provide

Waste Water And Its Treatment In Textile Industry

The textile wastewater discharged from printing and dyeing processes is characterized by high chemical oxygen demand (COD), low biochemical oxygen demand (BOD), and heavy colour. It is one of the...

Get Price

Wastewater in Textile Industry - Arvind Envisol

Finally, the last step is for ZLD or “Zero Liquid Discharge”. In this step, Evaporator (PFET) and Crystallizer (MEE) are used further to treat the reject of tertiary treatment. The recommended process in this final step is “Polymeric Film Evaporation Technology” (PEET).

Get Price

Textile Industry Wastewater Treatment | DAS

Wastewater Treatment in the Textile Industry: Clean Water Despite Demanding Production Processes The textile industry is an intensive producer of wastewater. The wastewater produced during the production of yarns and fabrics contains a very diverse range of chemicals and dyes.

Get Price

A REVIEW OF THE TEXTILE INDUSTRIES WASTE WATER TREATMENT

The textile industry effluents which are discharged are treated with various physical and chemical treatments such as coagulation, flocculation, ozonation and biological treatment for the removal of nitrogen, phosphorous, organics and metal traces. The disadvantages of the

Get Price

Textile Wastewater Treatment Options: A Critical Review

Textile industry is one of the largest water-consuming industries in the world, and its wastewater contains many pollutants such as dyes, degradable organics, detergents, stabilizing agents,...

Get Price

What are process controls for treating wastewater

Effective treatment of textile wastes, as with most types of industrial waste, begins in the manufacturing process itself. To improve wastewater treatment capability, consider flow reduction, water reuse, waste segregation, process or material substitution, and good housekeeping.

Get Price

Textile wastewater treatment | Wastewater in the textile

Textile wastewater treatment: how to get rid of colors in textile wastewaters How to get rid of colour in textile wastewater. The textile industry is characterized by the fact that its activity requires a high consumption of water, energy and auxiliary chemical products.

Get Price

Textile Wastewater Treatment: A Critical Review – IJERT

According to the World Bank estimation, textile dyeing and finishing treatment given to a fabric generates around 17 to 20 percent of industrial waste water [2], [3]. In India, the textiles industry consumes around 80% of the total production of 1, 30,000 tons of dyestuff, due to high demand for polyester and cotton, globally [4].

Get Price

Treatment and Recycling of Wastewater from Textile Industry

Textile industries are one of the largest generator of wastewater as large amount of water is used in coloring and finishing processes. The effluents released from textile industries contain biodegradable and non-biodegradable chemicals such as dyes, dispersants, leveling agents etc.

Get Price

METHODS FOR WASTE WATERS TREATMENT IN TEXTILE INDUSTRY

Keywords: textile industry, waste water, pollution, treatment. INTRODUCTION The textile industry is one of the largest and most complicated industrial chains in manufacturing industry. The production of a textile requires several stages of mechanical processing such as spinning, knitting, weaving, and garment production, which seem to be

Get Price

Textile Dyeing Wastewater Treatment - IntechOpen

Textile Dyeing Wastewater Treatment Zongping Wang, Miaomiao Xue, Kai Huang and Zizheng Liu Huazhong University of Science and Technology China 1. Introduction Textile industry can be classified into three categories viz., cotton, woolen, and synthetic fibers depending upon the used raw materials. The cotton textile industry is one of the

Get Price

Textile industry – WKS Group – Water.Wastewater.Energy

We offer turnkey, integrated solutions and individual concepts for water and wastewater treatment in the textile industry. The optimum process technology is selected, taking into consideration the operational requirements, the need to minimise disposal quantities and energy consumption and/or to generate energy.

Get Price

Wastewater treatment in the textile and tannery industries

Membrane products for the textile and tannery industries. The textile industry is one of the most water-intensive production industries in the world. Water is used throughout the manufacturing process and is critical for various flushing procedures. As a result, high volumes of wastewater are generated that contain high organic pollutants, high

Get Price

Textile wastewater treatment | Wastewater in the textile

Textile wastewater treatment: how to get rid of colors in textile wastewaters How to get rid of colour in textile wastewater. The textile industry is characterized by the fact that its activity requires a high consumption of water, energy and auxiliary chemical products.

Get Price

Textile Wastewater Treatment for Water Reuse: A Case Study

The reduced natural waters and the large amount of wastewater produced by textile industry necessitate an effective water reuse treatment. In this study, a combined two-stage water reuse treatment was established to enhance the quality and recovery rate of reused water. The primary treatment incorporated a flocculation and sedimentation system, two sand filtration units, an ozonation unit, an

Get Price

METHODS FOR WASTE WATERS TREATMENT IN TEXTILE INDUSTRY

Keywords: textile industry, waste water, pollution, treatment. INTRODUCTION The textile industry is one of the largest and most complicated industrial chains in manufacturing industry. The production of a textile requires several stages of mechanical processing such as spinning, knitting, weaving, and garment production, which seem to be

Get Price

Textile industry – WKS Group – Water.Wastewater.Energy

We offer turnkey, integrated solutions and individual concepts for water and wastewater treatment in the textile industry. The optimum process technology is selected, taking into consideration the operational requirements, the need to minimise disposal quantities and energy consumption and/or to generate energy.

Get Price

Impact of the Textile Industry on the Environment

The textile industry uses millions of gallons of water everyday. That's because to produce 1 kg of fabric, typically, 200 litres of water are consumed: washing the fiber, bleaching, dyeing and then cleaning the finished product. The problem does not rest in the high usage, though, but in the fact that often waste waters are not treated to remove pollutants before they are disposed in the

Get Price

Pollutants of Textile Industry Wastewater and Assessment

In this study, 11 textile mills that have treatment facility were chosen to investigate their material production, use of processed water, wastewater production, and treatment facility. The cost of treatment from these plants is also investigated. The products and processes of these 11 mills are summarized in Table 1. When these industries were

Get Price

What are process controls for treating wastewater

Effective treatment of textile wastes, as with most types of industrial waste, begins in the manufacturing process itself. To improve wastewater treatment capability, consider flow reduction, water reuse, waste segregation, process or material substitution, and good housekeeping.

Get Price

Textile wastewater treatment | Wastewater in the textile

Textile wastewater treatment: how to get rid of colors in textile wastewaters How to get rid of colour in textile wastewater. The textile industry is characterized by the fact that its activity requires a high consumption of water, energy and auxiliary chemical products.

Get Price

Industrial wastewater treatment | Condorchem Envitech

Textile industry. Textile industry wastewater contains organic matter, suspended solids and color. The things that we have to keep in mind with textile industry wastewater treatment is, depending on the textile process, the wastewater may contain high levels of pollutants. Energy production plants and the oil and gas sector

Get Price

Characteristics and Sources of Wastewater in Textile Industry

Introduction: Textile wastewater contains a large variety of dyes and chemical that make the environmental hazardous for textile industry not only as liquid waste but also in its chemical composition. Dyeing and finishing industry are mainly responsible to produce a large amount of waste water. This processes done by the input of a wide range of chemicals and dyestuffs or pigments, which

Get Price

Textile Wastewater Treatment and Zero Discharge Concept

It has also Bio-energy benefit and sludge production is very low compared to conventional treatment process. Treated wastewater could be recycled and reused in the textile industry…

Get Price

Fashion, the textile industry and wastewater: Q&A with

Fashion, the textile industry and wastewater. Amira Jehia is the co-founder and board member of Drip by Drip, a nonprofit organization committed to tackling the wastewater issue of the fashion and textile industry.With our current climate crisis, access to clean water becomes increasingly important.

Get Price

TEXTILE DYEING WASTEWATER AND TREATMENT SOLUTION

The textile and garment sector is playing an important role in Vietnam's economy. Beside its great contribution to the development of Vietnam, the textile and garment industry have also brought some negative impacts on the environment, especially wastewater sources from the production process.

Get Price

Water conservation in textile industry - SSWM

water and wastewater treatment. In addition to the direct cost sav-ings, a water conservation program can reduce the capital costs of any required end-of-pipe wastewater treatment system. Personnel from textile industry need to be aware of water conservation poten-tial so they can help their organization realize the benefits.

Get Price- What is polyaluminium chloride?

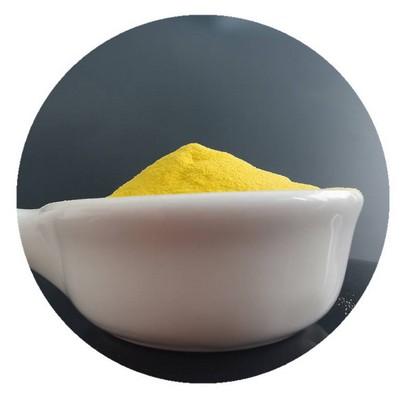

- Polyaluminium Chloride (PAC) is an inorganic polymer coagulant. It is a yellow solid powder that is widely used in water treatments. PAC is better than other aluminum salts such as aluminium chloride, aluminium sulphate, and other various forms of Polyaluminium chlorisulfate and Polyaluminium chloride that they have lower charge than PAC.

- What is white poly Aluminium chloride?

- White Poly Aluminium Chloride is also known as high purity without iron white Polyaluminium chloride, Food Grade,Drinking/Potable Water Grade white polyaluminium chloride , compared with other polyaluminium chloride is the highest quality PAC.

- What is white poly Aluminium chloride production process?

- White Poly Aluminium Chloride production process is the most advanced technology of spray drying method. PAC is easy to be damp when it is exposed in the air. Strong electric neutralization of colloidal substance in drinking and potable water. The pac solution have the good adsorption bridging function for suspended solids in water.

- What is white powder (spray) polyaluminium chloride?

- White Powder (Spray) Polyaluminium Chloride is specialized inorganic aluminum salts chemicals for drinking water treatment. CAS No.:1327-41-9 EINECS No.:215-477-2 Molecular Formula:【AL2 (OH)nCL6-n】 White Poly Aluminium Chloride production process is the most advanced technology of spray drying method.